Rury PE 100-RC

< FM APPROVED >

Technical characteristics:

Pipes and fittings made of PE 100-RC SDR11 polyethylene with FM Global certification intended for pressure pipes (fire-fighting installations, water pipelines, gas fuels, pressure and vacuum sewerage) and gravity pipes (sanitary sewerage, drainage), as well as for making culverts under road embankments laid underground in the road lane.

Tests of the pipes carried out at the HESSEL Ingenieurtechnik GmbH institute and the Oil and Gas Institute in Krakow confirm their resistance to the effects of scratching and point loads, which may arise as a result of constructing networks in native soil without the use of bedding and backfilling as well as for constructing and renovating networks using traditional and trenchless methods.

Depending on the diameter and intended use, pipe sections can be joined using the following methods:

– butt welding

– electrofusion welding

– joining using compression fittings

Przeznaczenie

Intended use

They are intended, among other things, for the construction of fire-fighting networks, water supply networks, sewage networks and for the transport of aggressive liquids.

-

The transmission of water intended for supply to fire-fighting installations

-

the transport of water for human consumption

-

The transmission of water before it is treated

-

Water intended for other uses

-

Pressure systems for rainwater and sanitary sewerage systems

-

Vacuum sewer systems

PE pipes HD 100-RC for water supply and fire protection systems according to PN=EN 12201-2, working pressure: 16 bar, Certificates: FM Global

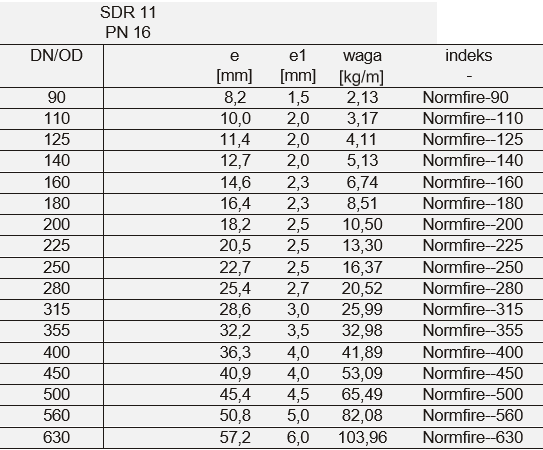

Wymiary : wymiar odniesiony do średnicy zewnętrznej DN/OD średnica

Średnica DN 90 – 630 – odcinki prote o standardowej długości 12 m

Inne długości rur na zapytanie

Kolor : średnica DN 90 – 630 wartstwa wewnętrzna : czarna; warstwa zewenętrzna: czarna

Standards

-

PN-EN 12201-2+A:2013-12 Plastic piping systems for water conveyance and for pressure rainwater and sanitary sewerage – Polyethylene (PE)

-

PN-EN 12201-3+A:2013-05 Plastic piping systems for water conveyance and for pressure rainwater and sanitary sewerage – Polyethylene (PE)

Certification of the pipe

-

FM GLOBAL : Examination Standard for Polyethylene (PE) Pipe and Fittings for Underground Fire Protection Service

-

GIG Opinion BL-/22-96 : Technical opinion on the possibility of using PE100 and PE100-RC polyethylene pipes and fittings in mining areas.

Certification of fittings

-

FM GLOBAL : Examination Standard for Polyethylene (PE) Pipe and Fittings for Underground Fire Protection Service.

-

Bureau Veritas Certifcation, SGS Certfication, KIWA, SVGV, WaterMark, FVGV

Advantages of the NORMFIRE system for fire and water supply networks :

-

High strength of material ensures safe installation in all conditions

-

Polyethylene has a high chemical resistance to most chemicals

-

The detection insert makes maintenance of the pipeline even easier

-

PE 100 RC pipes are certified according to PAS 1075:2009-04 for alternative laying techniques

-

NORMFIRE pipes can be joined by butt and electrofusion welding or compression fittings.

-

For connection to fittings or pipelines made of materials other than PE, flanged fittings, suitable mechanical couplings or PE/steel transition fittings can be used.

-

Tests of the pipes carried out at the HESSEl Ingenjeurtechnik GmbH institute and the Oil and Gas Institute in Krakow confirm their resistance to the effects of scratching and point loads, which may arise as a result of constructing networks in native soil without the use of bedding and backfilling, as well as for the construction and renovation of networks using traditional and trenchless methods.

Production

Production takes place at the Kaczmarek Malewo plant, one of the largest Polish suppliers of PE piping systems.

The company’s history dates back to 1985, when the PPHT Barbara Kaczmarek – Malewo company, managed by four brothers, started its activity – from the production of haberdashery and technical film from softened PVC. The plant started up producing film for notebook covers, bag linings, films for folding doors, prams and mattresses. By 1994 the company was one of the main suppliers of this material for the FSO plant, which installed our product in car doors.

1985 -Started production of PVC film

1991 – Construction of the first production hall and purchase of the first extruder for tube production

1993 – New production lines for the manufacture of large diameter sewage and pressure pipes

1997 – Establishment of a new production hall in Piaski

1999 – Market launch of a new manhole system

2003 – Commencement of the production of the large-diameter external sewage system K2-Kan

2012 – Addition of Hydrobox infiltration boxes to the assortment

2014 – Launch of the K2-XXL production line